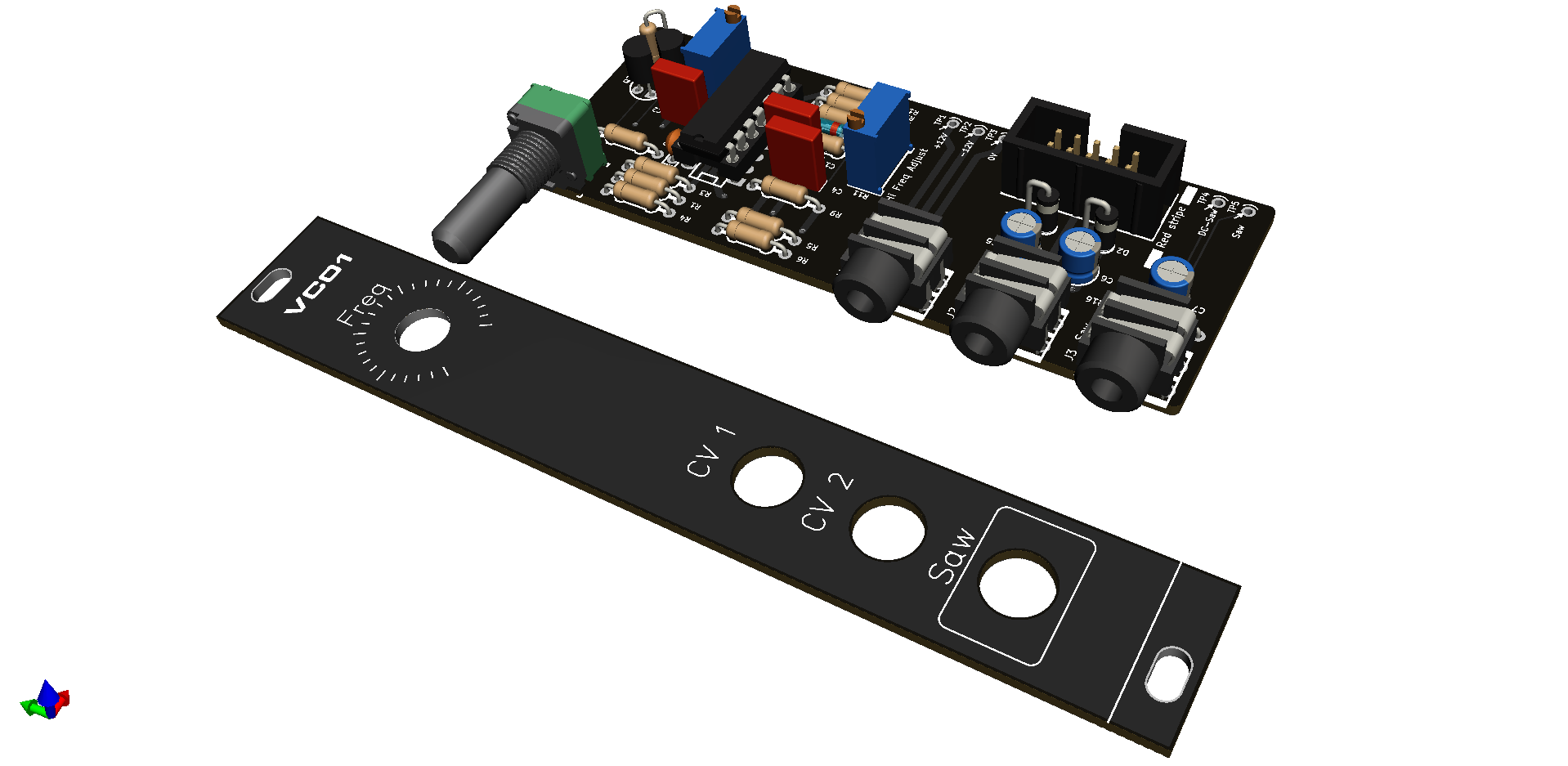

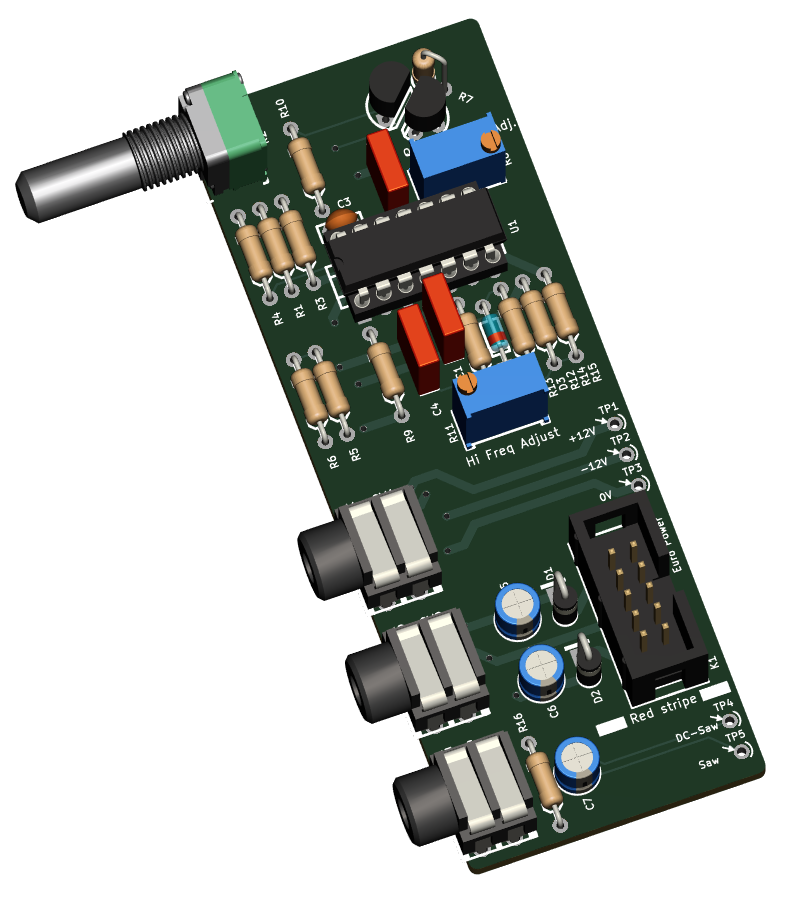

Following the Simple LFO module, here comes the Simple VCO.

It’s a very stripped down version of the Formant VCO, modified and adapted to the Eurorack format.

This circuit is also present in the VCO section of the DM77 Drum Module.

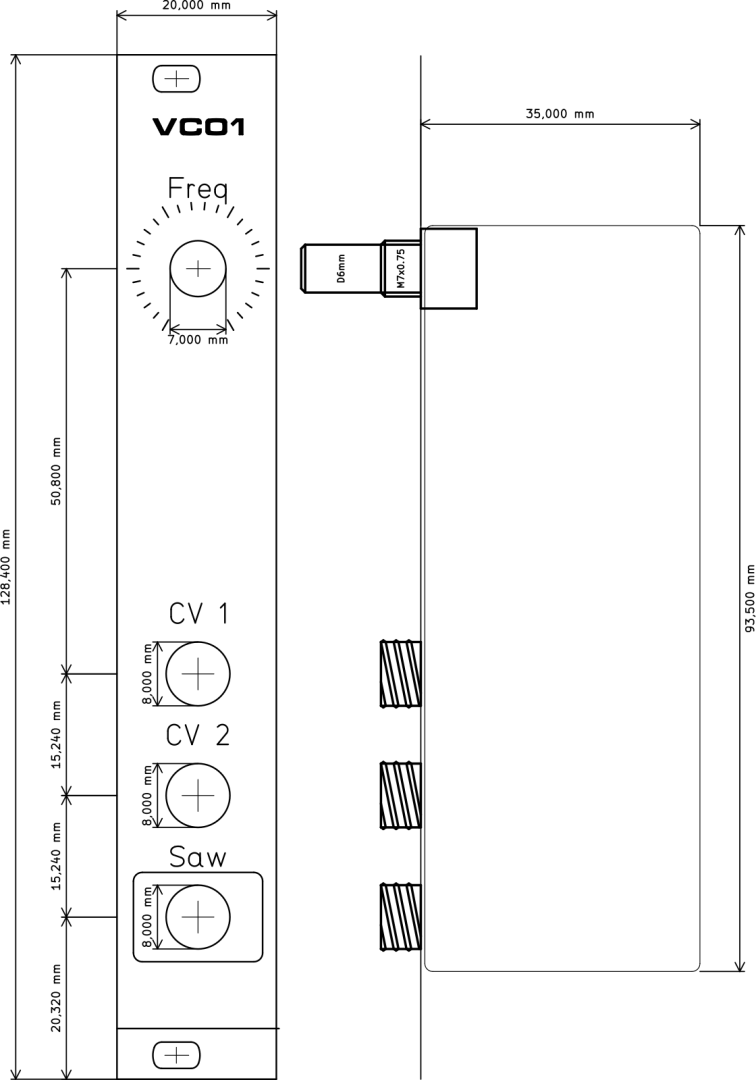

The Simple VCO is 1V/Oct capable. In order to reduce the number of parts, only one waveform output is available.

The result is a super simple module, easy to build, to understand and maintain.

An updated and improved version is available!

The circuit

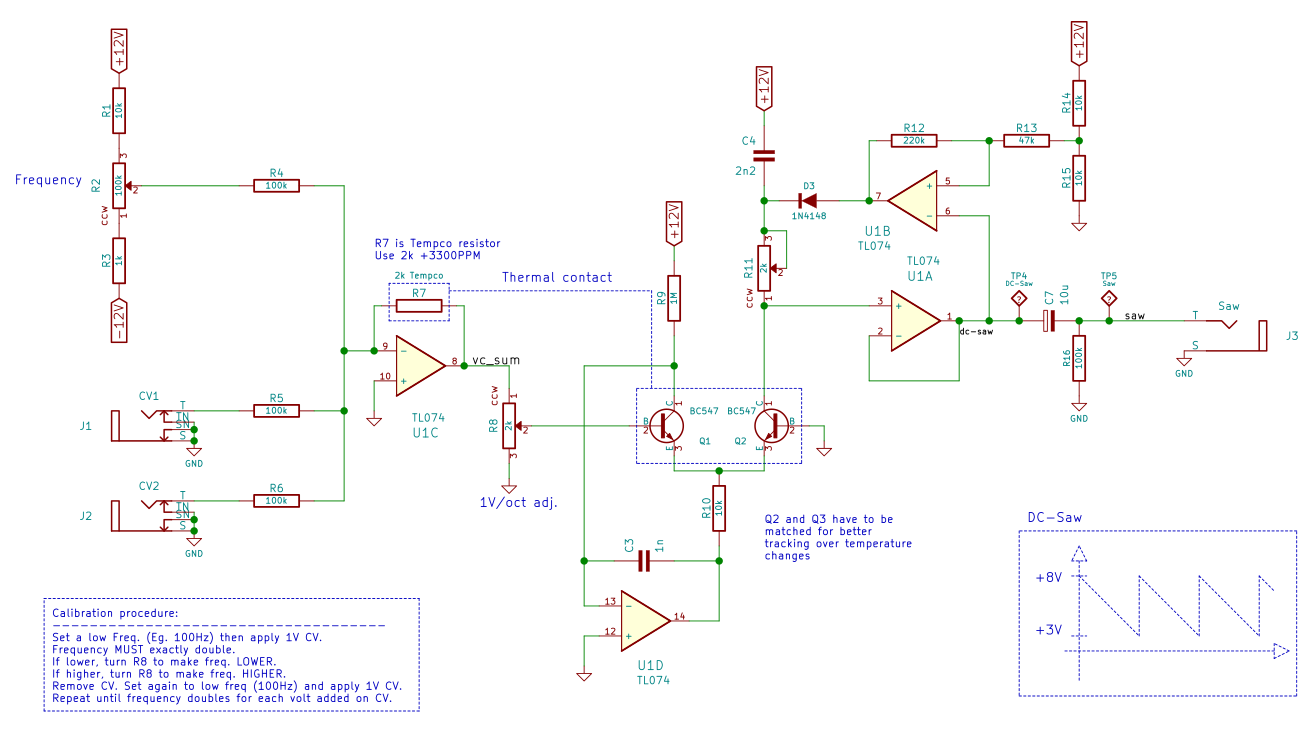

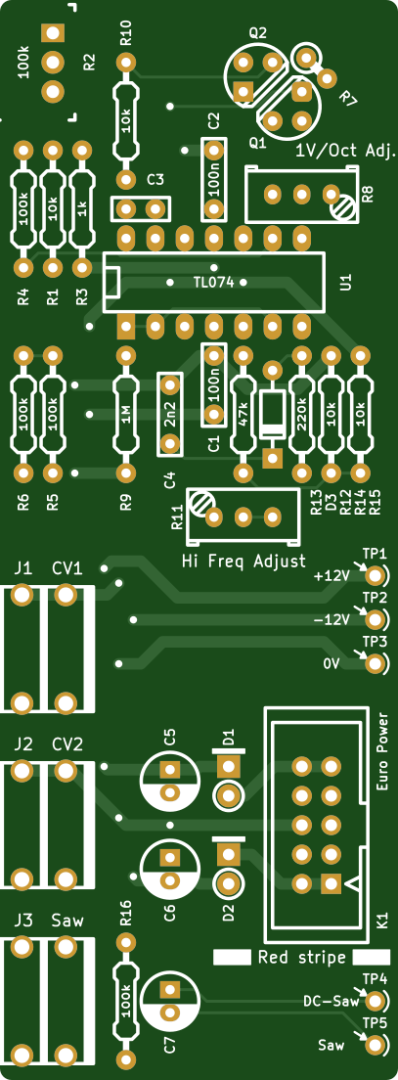

The oscillator is a “saw core” VCO, derived from the Formant VCO. There are some differences though: the comparator is an op amp (U1B) instead of a CMOS gate, and the switching transistor has been replaced with a simple diode (D3).

Potentiometer R2 is the main frequency setting. R1 and R3 define the upper and lower limits of the base frequency range.

The frequency is modulated by 2 external Control Voltages (CV): CV1 (J1) and CV2 (J2), through R5 and R6 respectively.

U1C is a summing amplifier. It sums the CVs and R7 is the 2k temperature-compensation feedback resistor. It is located close to the matched NPN transistor pair Q1 and Q2. R8 is responsible for adjusting the 1V/Octave tracking behavior. R11 is a high frequency compensation trimmer. When the CV increases, the frequency tends to go flat. Adjusting R11 allows to get better results on higher frequencies.

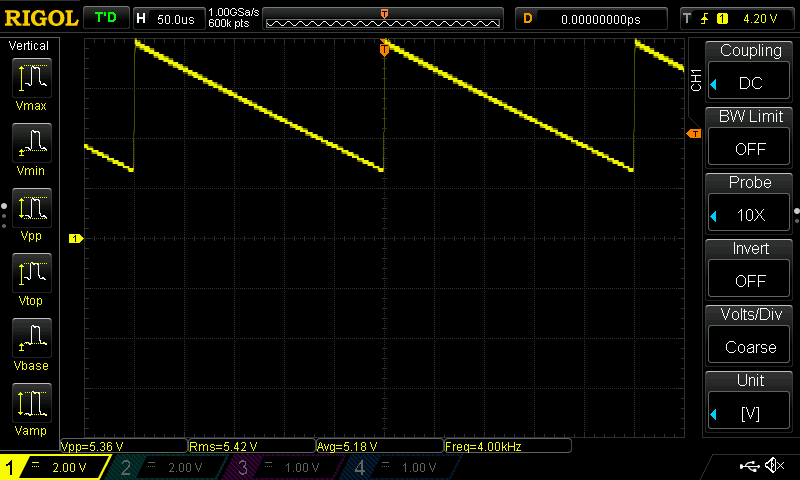

C4 is the capacitor where the saw tooth signal is generated: Q2 is a current sink and discharges at a constant rate C4. U1A follows the voltage variation and U1B compares that value to a known voltage determined by R14 and R15.

The raw saw tooth signal (DC-Saw) goes roughly from +8V to +3V. Around +3V, U1B triggers and sends a very brief positive voltage spike to the negative side of C4, through D3. This increase in voltage quickly charges C4 and resets back U1B and the capacitor starts again to discharge.

It is important to note that the VCO relies at several places on the power supply rails for its voltage references. Any voltage variation on the rails will be noticeable in the frequency.

Calibration and first tests

Powering on

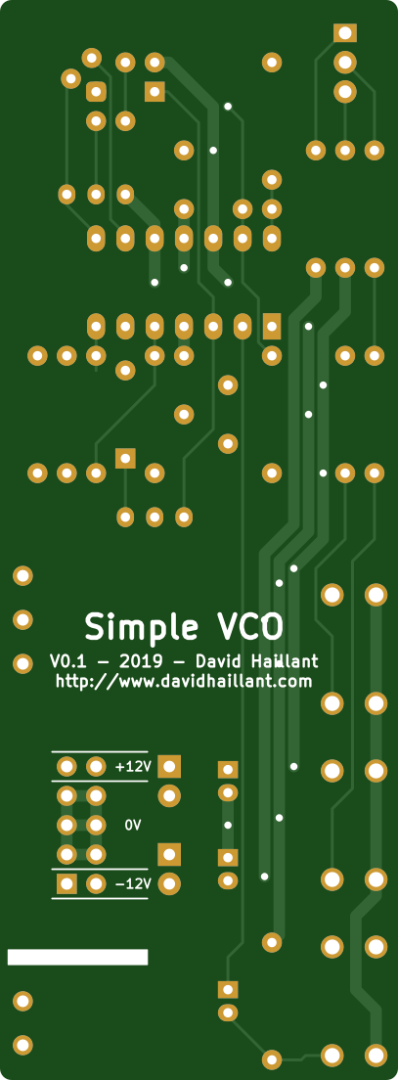

Once you think you’ve soldered everything correctly, before powering your module for the first time, check twice that you haven’t put anything backward and that the power input connector is correctly oriented, and your power cable is trust worthy!

Furthermore, I recommend to power the module the first time without any IC inserted and check with a multimeter the presence of the expected voltage rails on the correct pins.

VCO calibration

The calibration process is identical to any other VCO. The 10 turn trim potentiometer R8 sets the 1V/Octave conformance.

The second 10 turn trim potentiometer, R11, is the setting for the high frequency compensation.

The required tools are:

- An accurate voltage source, capable of delivering a CV in 1V steps (0V, 1V, 2V, etc.) MIDI to CV modules are great for this.

- A frequency meter or a tuner.

- A small flat blade screw driver.

- Your tongue at righ angle and some patience.

- Also a multimeter, because you always need a multimeter.

- And if you have an oscilloscope, it’s a good idea to monitor the waveforms.

R11 must be set first to the lowest resistance between pin 1 and 3. It’s in full Counter Clockwise position.

You can also read the oscillator frequency from Test Points TP4 and TP5.

- The first step is to apply no CV input (0V) and turn the potentiometer R2 to set the main oscillator frequency at a low value. If you use a frequency meter, you can set the frequency to an easy-to-read value of 100Hz, for example. If you’re using a tuner, or your ears, tune the main oscillator to precisely A2 (110Hz).

- Then apply a 1V source on the CV input. The frequency of the main oscillator should double (200Hz or A3). If the frequency is flat, then adjust the trim potentiometer R8 and make the frequency go a bit flatter. If the frequency is sharp, then adjust R8 to set the frequency a bit sharper.

- Go back to 0V on CV input. Now the frequency is no more 100Hz (or A2). Adjust R2 back to 100Hz precisely (or A2).

- Repeat step 2, until the frequency doubles exactly when 1V is applied to the CV input.

- You can then check if the VCO frequency doubles again with a CV at 2V. The frequency must be 4x the base frequency (400Hz or A4).

- Do the same for 3V, 4V, etc. The frequency must double for each volt added on the CV input.

- At a certain point, the frequency will start to flatten, no matter how precisely you tuned the VCO on the lower octaves. You now need to adjust the second trim potentiometer R11. Turn clockwise R11 to increase the frequency. Once you’re back in tune, return to step 2 and start over.

After a number of iterations, the VCO is able to stay in tune for several octaves. The number of in-tune octaves depends on several factors. The quality of the transistors, among others. The matching of the transistors has no relation to how well the VCO will track. It only corrects the frequency drifts caused by temperature changes.

Appreciate this effort, will build it and report back, thank you!